LNG 공정용 극저온 밀봉: 스프링 구동 솔루션으로 극한 조건 극복

액화천연가스(LNG) 공정에서 밸브와 장비는 지구상에서 가장 혹독한 환경에 노출됩니다. 영하 320°F(-196°C) 이하의 저온, 750psi를 초과하는 압력, 그리고 장비의 팽창, 수축 및 재료 응력을 유발하는 지속적인 열 순환이 그것입니다. 이러한 극한의 환경 속에서 안전하고 누출 없는 작동을 보장하면서 장기간 동안 밀봉 상태를 유지할 수 있는 밀봉재가 필수적입니다.

Efficient, reliable valve performance is critical to the success of any LNG/CNG operation, and seals play a central role in keeping valves up and running. But their job is made difficult by the demanding service conditions.

Challenges in LNG Valve Sealing

LNG operations subject seals to unique stresses:

Spring-energized seals are vital across LNG infrastructure, including:

With the right material formulation and design, they can actually provide much better sealing service than alternative technologies, such as metallic seals, elastomeric seals and packings—especially in dynamic applications. In fact, the right polymer seals can actually help engineers achieve new levels of valve performance.

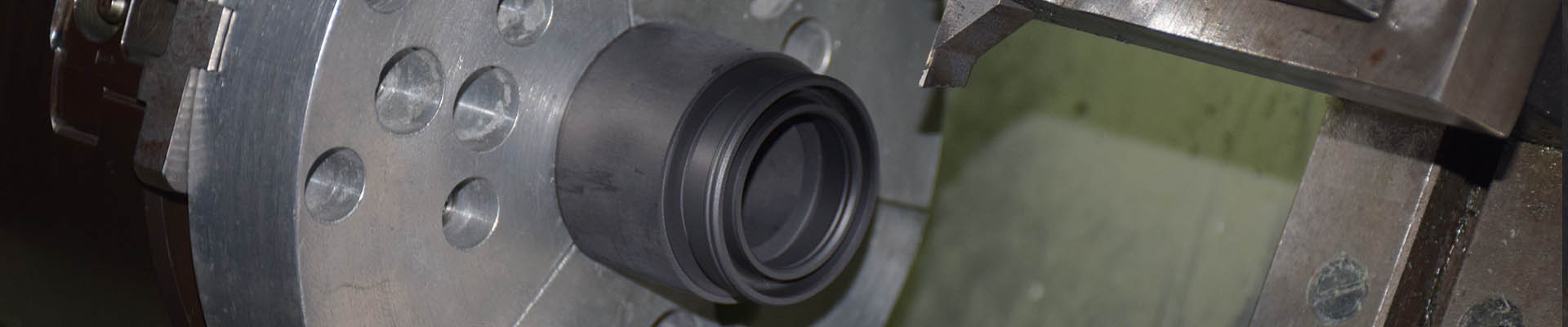

Sealing at cryogenic temperatures has its own unique set of challenges. JST has a wide range of solutions for cryogenic sealing applications. Cryogenic seals require skillful design by combining the right type of material, seal configuration, and spring energizer to overcome the dimensional fluctuation of all mating parts.

Upgrade your LNG systems with JST’s cryogenic sealing solutions —engineered to keep your operations running smoothly, safely, and leak-free.

© 저작권: 2026 Guangzhou JST Seals Technology Co., Ltd. 판권 소유.