폴리머 씰 성능에 있어 표면 마감이 중요한 이유는 무엇일까요?

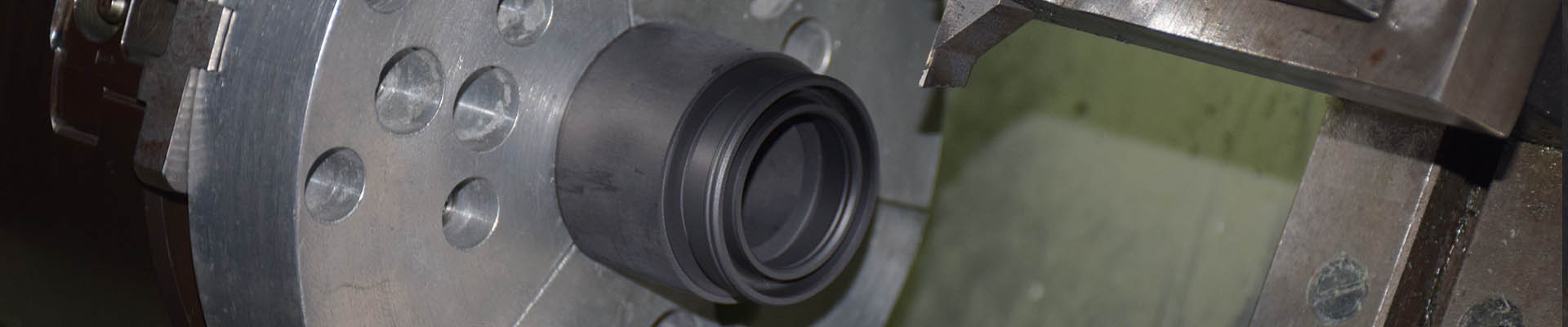

표면 마감은 매우 중요한 요소입니다. 폴리머 씰 표면 질감은 밀봉 효과, 마찰력 및 내구성에 직접적인 영향을 미치기 때문에 성능에 매우 중요합니다. 거친 표면에 잘 밀착되는 부드러운 엘라스토머와 달리, 대부분의 고분자 소재는 단단하여 안정적이고 오래 지속되는 밀봉을 위해서는 특정한 표면 질감이 필요합니다.

표면 마감이 중요한 주요 이유:

고려해야 할 주요 매개변수

표면조도 평균(Ra)은 흔히 사용되는 지표이지만, 이것만으로는 모든 것을 설명할 수 없습니다. 다음과 같은 다른 중요한 매개변수도 고려해야 합니다.

Rz: 평균 거칠기 깊이로, 가장 높은 봉우리와 가장 낮은 골짜기 사이의 평균 높이 차이에 초점을 맞춥니다.

시공 방향: 표면 패턴의 주요 방향(예: 직선형 vs. 교차형). 왕복 운동하는 도포 과정에서 이동 방향과 평행한 직선형 마감은 교차형 패턴보다 누수 경로를 생성할 가능성이 더 높습니다.

경도: 접합면의 경도 또한 중요한 요소입니다. 일반적으로 씰이 하드웨어를 손상시키는 것을 방지하기 위해 단단한 표면(예: 40~60 Rockwell C)이 권장되지만, 이로 인해 초기 표면 마감 품질이 더욱 중요해집니다.

궁극적으로 폴리머 씰 적용에 이상적인 표면 마감은 씰 재질(예: PTFE 대 엘라스토머), 적용 분야가 정적인지 동적인지, 그리고 밀봉 대상 매체의 종류(기체, 액체 등)를 고려하여 신중하게 선택해야 하는 특정 범위입니다.

일반적인 표면 마감 권장 사항

|

적용 분야/재료 |

일반적인 권장 Ra 범위 |

|

엘라스토머(고무) 씰 |

|

|

폴리머(PTFE 등) 씰 |

|

|

밀봉 가스 / 극저온 |

매우 훌륭하고, 최저 수준입니다.

|

|

일반적으로 약간 거친 마감을 견딜 수 있습니다. 동적 씰 |

요약하자면, 올바른 표면 마감 처리를 선택하는 것은 매우 중요한 엔지니어링 고려 사항입니다. 단순히 부품을 보기 좋게 만드는 것만이 아니라, 폴리머 씰이 최상의 작동 성능과 수명을 달성하는 데 필요한 정확한 미세 환경을 제공하는 것이 핵심입니다.

© 저작권: 2026 Guangzhou JST Seals Technology Co., Ltd. 판권 소유.